Introduction

In the fast-paced world of business operations, effective inventory control is paramount to sustaining profitability, ensuring customer satisfaction, and maintaining operational efficiency. Business inventory control encompasses the systems, tools, and strategies that companies use to manage, track, and optimize their stock levels. From small retail stores to multinational manufacturers, inventory control plays a crucial role in streamlining supply chains, reducing waste, and improving financial performance.

This article provides a detailed examination of business inventory control in 2025, exploring its core principles, modern technologies, best practices, challenges, and future trends.

Chapter 1: What is Business Inventory Control?

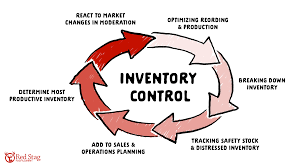

Inventory control, often referred to as stock control, is the process of managing a company’s inventory to ensure the right amount of products are available at the right time. It involves monitoring stock levels, managing reorders, minimizing carrying costs, and reducing losses due to theft, spoilage, or obsolescence.

Inventory control is not just about counting items; it’s about using data-driven decisions to balance supply and demand. It includes both raw materials and finished goods and is essential for businesses in sectors such as retail, manufacturing, e-commerce, and logistics.

Chapter 2: Key Components of Inventory Control

- Inventory Tracking: Real-time tracking of inventory across warehouses, stores, and distribution centers.

- Stock Replenishment: Systems to determine when and how much to reorder.

- Demand Forecasting: Predicting future product demand using historical sales data and market trends.

- Inventory Auditing: Regular physical counts to match system records.

- SKU Management: Organizing stock by stock-keeping units for precise control.

- Valuation Methods: Methods such as FIFO (First In, First Out), LIFO (Last In, First Out), and weighted average costing.

Chapter 3: Types of Inventory

- Raw Materials: Basic materials used in the production of goods.

- Work-in-Progress (WIP): Items that are in the process of being manufactured.

- Finished Goods: Products ready for sale.

- MRO Goods: Maintenance, repair, and operations supplies needed for production.

Chapter 4: Importance of Inventory Control

Effective inventory control leads to:

- Cost Savings: Reduced storage costs and minimized losses.

- Customer Satisfaction: Timely fulfillment of customer orders.

- Operational Efficiency: Streamlined processes and reduced production delays.

- Accurate Financial Reporting: Better visibility of assets and expenses.

Chapter 5: Technologies Driving Modern Inventory Control

- Inventory Management Software: Platforms like NetSuite, Zoho Inventory, and Fishbowl automate and centralize inventory data.

- Barcode and QR Code Systems: Facilitate real-time tracking and scanning.

- RFID (Radio Frequency Identification): Provides real-time inventory visibility.

- IoT Devices: Sensors that monitor inventory conditions like temperature and movement.

- Cloud Computing: Enables remote access and data synchronization across locations.

- AI and Machine Learning: Enhance demand forecasting and optimize reorder points.

- Mobile Apps: Allow inventory management from handheld devices.

Chapter 6: Best Practices for Inventory Control

- ABC Analysis: Prioritize inventory based on importance and value.

- Just-in-Time (JIT): Keep minimal stock and reorder as needed.

- Cycle Counting: Frequent counting of portions of inventory.

- Inventory Turnover Ratio Monitoring: Measure how often inventory is sold and replaced.

- Safety Stock Levels: Maintain a buffer to prevent stockouts.

- Vendor Management: Cultivate strong supplier relationships.

Chapter 7: Challenges in Inventory Control

- Inaccurate Data: Errors in records can lead to stockouts or overstocking.

- Demand Variability: Unexpected changes in demand can disrupt stock levels.

- Supply Chain Disruptions: Delays or shortages can affect inventory.

- Warehouse Inefficiencies: Poor layout or mismanagement can lead to losses.

- Obsolete Inventory: Unsold items that become outdated or expire.

Chapter 8: Inventory Control for Different Business Models

- Retail: Focus on fast-moving items, seasonal demand, and promotions.

- Manufacturing: Requires synchronization with production schedules.

- E-commerce: Needs real-time stock updates and seamless logistics.

- Wholesale and Distribution: Involves large-scale inventory handling and fulfillment.

Chapter 9: Metrics and KPIs for Inventory Control

- Inventory Turnover Ratio

- Days Sales of Inventory (DSI)

- Stockout Rate

- Carrying Cost of Inventory

- Order Accuracy Rate

- Gross Margin Return on Inventory (GMROI)

Chapter 10: Case Studies of Successful Inventory Control

- Zara: Uses real-time data to manage rapid production and store replenishment.

- Amazon: Leverages AI and robotics for warehouse automation and precision.

- Toyota: Pioneered JIT inventory control to minimize waste and increase efficiency.

Chapter 11: Future Trends in Inventory Control

- AI-Driven Forecasting: Advanced analytics for better planning.

- Blockchain Technology: Enhances transparency and traceability.

- Sustainable Inventory Practices: Focus on reducing waste and environmental impact.

- Autonomous Warehousing: Use of drones and robots for inventory tasks.

- Integration with ERP and CRM: Unified systems for better decision-making.

Conclusion

Business inventory control is a cornerstone of efficient and profitable operations. As technologies evolve and market demands shift, companies must continuously adapt their inventory strategies to remain competitive. By embracing automation, data analytics, and best practices, businesses can transform inventory control from a logistical necessity into a strategic advantage.

Whether you’re managing a small business or a global enterprise, investing in robust inventory control systems in 2025 is essential for sustainable growth and customer satisfaction.